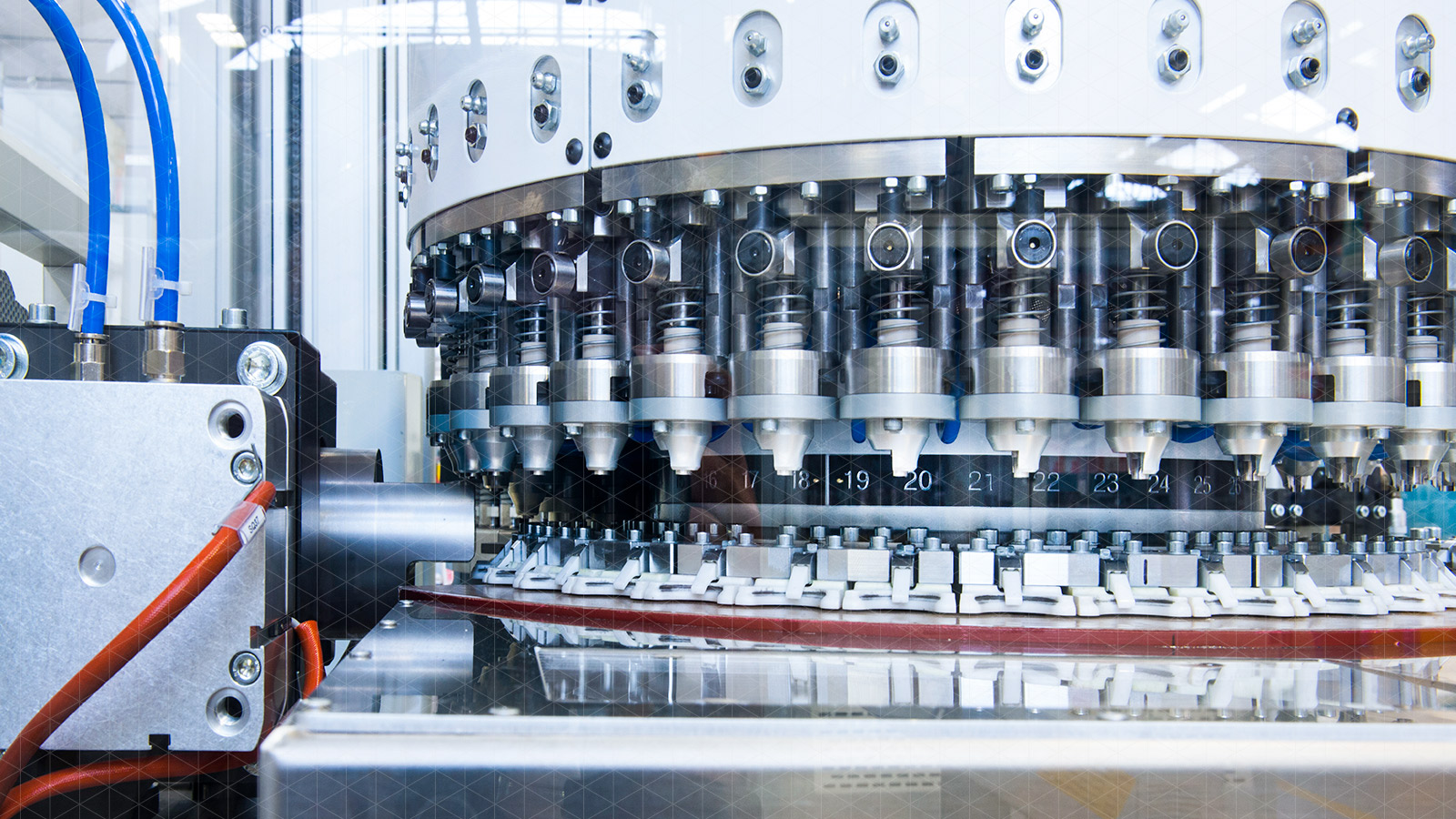

High speed lining machine process

Do you want your business to produce lined caps in large volumes and be able to meet market demand? Do you have limited space and are looking for equipment that can handle various cap sizes and different types of liner materials?

Rotary die-cutting technology, which is adaptable to multiple types of lining and is particularly effective for induction thermal liners, creates a pre-defined shape mark on the roll lining material, forming a band of pre-cut seals that remain adhered thanks to very fine retaining bonds.

The strip of pre-cut seals automatically advances to the insertion station on the lining machine where each piece of pre-cut liner is centered precisely in relation to the position of the lid. Once the part is correctly positioned, the insertion tool will be activated to break the web retention joint and place the lining part into the caps.

Given the high speed at which this equipment operates and the rate at which the cases are filled with the final product, it is recommended that a compact changer be used for case movement. This configuration allows several cases to be formed in line before being filled, thus minimizing operator intervention.

This also ensures that when the filled boxes are ready, they are at an ergonomically safe and appropriate height for the operator to lift them.

The LM-4 Liner Machine is powered by ICON controls technology, our PC-based platform is designed to increase throughput and optimize uptime.

Advantages of the LM-4 Lining Machine with rotary die cutting technology

Speed: up to 1,200 parts per minute or 72,000 parts per hour.

Versatility: can be used for different cap diameters and can handle different types of liner material

Noise reduction: rotary die technology significantly reduces machine noise and vibration level

Ease of transition: simple and fast component changeovers resulting in improved uptime as they are significantly lighter than transitions using traditional dies

Advanced capability: servo-driven rotary die registration mark

The high-capacity lining machine with rotary die technology provides time and space efficiency, as well as all of its cutting and inserting functions.

With a large selection of machines and a wide variety of packaging solutions to suit your needs, you’ll find everything you need to make your business run as smartly as possible.

The High Speed Hinged Bin Labeler is a stand-alone, flexible, continuous motion machine designed to label hinged garbage cans or trays and re-nest them with the tray counting feature for distribution.

The system uses a patented three-arm, four-stop, secondary motion rotary unscrambler to pick product, a 6-ft. infeed electric horizontal magazine to position product for labeling, and an 8-ft. outfeed electric horizontal magazine with guide belts to accumulate labeled products.

This lining machine has an integrated single labeler to label the top lid, or dual labelers can be integrated to label both the lid and the base.